Design Cases and examples

Pipe Support Design Options

Pipe Support Considerations

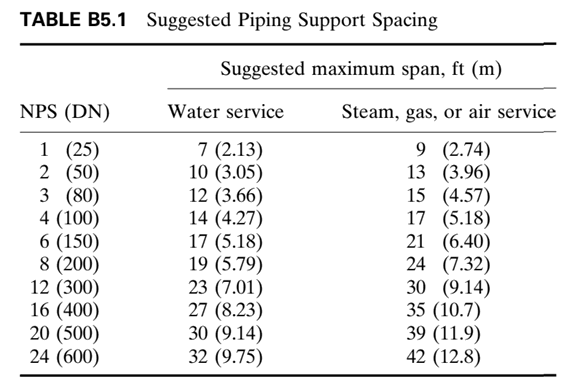

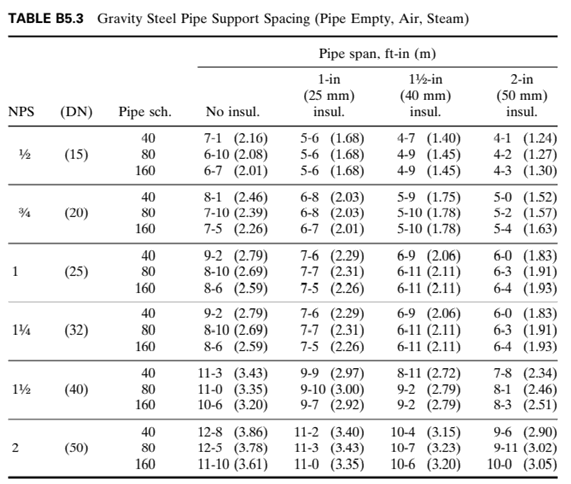

A central requirement in the successful application of a bellows expansion joint, is the use of appropriate supports, guides and anchors to control the movement of the pipe from thermal growth/contraction and foundation differential settlements. Together with cost effective piping, pipe supports are located in accordance within spans determined using structural behaviour of the materials of construction and the medium that includes the operating environment. It is not usual to consider any structural contribution from fittings such as flanges and valves, neither similarly from insulation and ice in the case of cryogenic piping, but the contribution of these to the weight of the pipe must be included as reflected in the spans in tables. The supports locations are first located as determined by available structural steels geometries before guides and intermediate anchors are identified.

The interactive design approach normally required for the supports needed in a new piping system means that the piping designer/engineer is required from the start of the plant design. Any delay in engaging a piping engineer only serve to cause project losses. When dealing multiple piping systems in a plant, it is always a good idea to represent the piping as line diagram superimposed on a drawing of the structural steelworks as this aid the possible locations of supports which can then be used together with the required pipe spans to specify the support locations.

Once the supports locations have been identified, a design assessment process using expected loads in all degrees of freedom at these locations to include support loads from static operating and occasional events of seismic, shock and hydrodynamic loads. Piping design standards such as ASME B31.3 for process piping allows for the basic allowable design stresses to be exceeded by up to 20 percent so long as these dynamic loads are occasional as defined in the applicable design standard. Most expansion bellows manufacturers have in-house application and design section that is capable of providing the necessary pipe supports and stress engineering, but others would outsource this vital safety service to design and application houses such as Dennet Expansion Bellows.

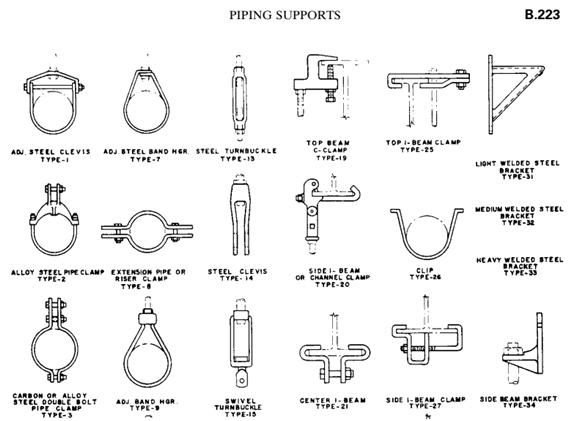

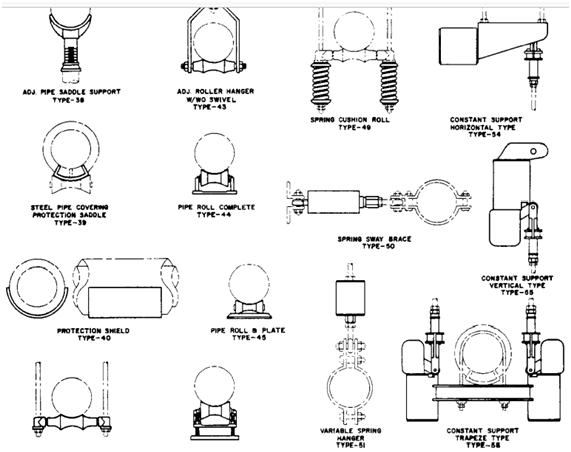

The following examples are extracts from piping handbook.

Typical Pipe Supports

- Extracts from Piping Handbook -

Pipe Support Manufacturer